додому Блог

Simmer pots are a growing trend in home fragrance – offering a natural, subtle alternative to candles and air fresheners. Experts recommend them for...

A recent TikTok trend has many questioning their kitchen habits: should flatware be stored side-by-side instead of stacked? The idea, popularized by organizing videos,...

Interior designers consistently point to certain bathroom features as instant style downgrades. Whether you’re renovating or just refreshing, avoiding these...

The start of a new year often inspires a desire for change, but extensive home renovations aren't always feasible. Interior designers overwhelmingly agree on...

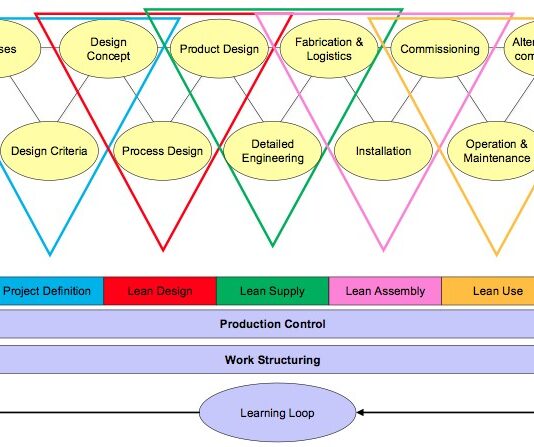

Large construction projects differ dramatically from smaller builds like homes. The sheer scale introduces complexity that simple project management alone can’t handle. To maximize...

For years, open-plan living spaces were the standard in modern home design—bright, airy, and seemingly ideal for social gatherings. However, a shift is underway....

Hosting Thanksgiving and other holiday gatherings can be stressful, from menu planning to managing guests. One way to reduce this stress is by adopting...

The Lean Project Delivery System (LPDS), first introduced by Glenn Ballard in 2000, represents a fundamental shift in how construction projects are managed. Unlike...

Sweaters, while essential for cooler seasons, take up significant space when folded. Hanging them offers a space-saving solution, but improper methods can lead to...

The construction industry is shifting toward greater collaboration and reduced conflict, leading to the emergence of methodologies like Integrated Project Delivery (IPD). In response,...

The construction industry often lags behind manufacturing in adopting efficient production systems. One key difference lies in workflow: while manufacturing relies on stationary machines...

Зміст

ToggleМагія любові: реальність, психологія та мистецтво створення гармонійних стосунківЛюбов магія: міф чи реальність?Психологія ритуалів: Чому вони працюють?Давайте подивимось на популярні заклинання: що вони насправді...

Зміст

ToggleДомашні хаки життя: ілюзія заощаджень чи шлях до нових проблем?Штучний декор: краса обманює?Затирка: протизахисний герметикПідроблений мармур: фарба проти епоксидноїВідродження затирки з фарбою: міф чи...

Зміст

ToggleЖаби: Життя на межі виживання в харчовій ланцюзіПостійна загроза: хто полює на жаб?Жаби як хижаки: полювання на комах та іншеВразливість та адаптація: як виживають...

Посилайте свій акваріум: 10 барвистої риби, щоб створити підводний світ вашої мрії Акваріум - це не просто резервуар з водою та рибою. Це жива...

Зміст

ToggleЧому моя кішка не муркоче? Розбираємося в котячому мовою і не тількиМуркотіння: не тільки ознака щастяІндивідуальність котячого характеруАльтернативні способи вираження емоційКоли варто турбуватися?Котячі родичі:...

Саморобки: між економією та катастрофою-особистий досвід та уроки Саморобки-це спокуса. Особливо зараз, коли в соціальних мережах можна побачити неймовірні перетворення ванних кімнат, кухонь і...

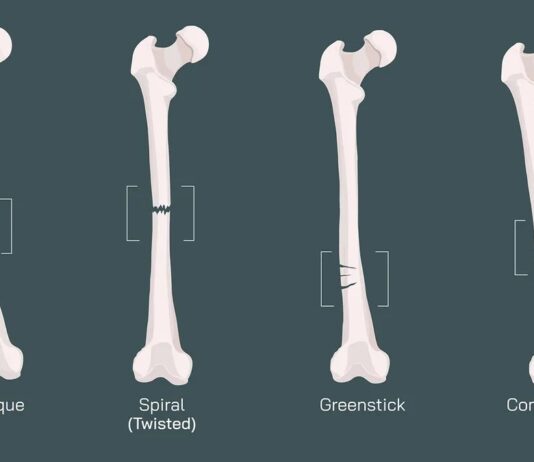

Перелом кістки - це не просто біль і гіпс. Це складний процес, що вимагає розуміння механіки пошкодження, діагностики та грамотного відновлення. Багато хто...

Зірчастий жасмин: створюємо ароматний оазис в саду своїми руками Зірчастий жасмин (Trachelospermum jasminoides) - це не просто рослина, це можливість перетворити ваш сад, створивши...

Чи варто взагалі фарбувати підлоги? Це можливо, але тільки за умови, що ви будете слідувати цим рекомендаціям експертів

maxwelhelp - 0

Фарбування підлоги: чи варта гра свічок? Розбираємося з експертами і своїм досвідомУ світі дизайну інтер'єру та ремонту своїми руками, ідея перетворити простір часто зводиться...

Цікаве

Рекомендуемо

Chocogra Chewable 100 мг: Революційний жувальний дженерик Віагри для миттєвої чоловічої сили!

maxwelhelp - 0

Уявіть собі: романтичний вечір, пристрасні обійми, і ви — на піку форми, без жодних "провалів"! Chocogra Chewable 100 мг — це інноваційний дженерик Віагри...

Щоденні звички, що реально покращують самопочуття

maxwelhelp - 0

Ми часто шукаємо складні рішення для простих проблем, хоча стабільний настрій і хороше самопочуття часто народжуються з кількох дуже буденних кроків. Нижче зібрана структурована,...

Türöffnungen in Berlin – Alles, was Sie wissen müssen

maxwelhelp - 0

Das Thema Türöffnungen in Berlin ist für viele Menschen relevant, denn jeder kann irgendwann in die Situation geraten schlusseldienst Berlin preise, dass er ausgesperrt...