The Lean Project Delivery System (LPDS), first introduced by Glenn Ballard in 2000, represents a fundamental shift in how construction projects are managed. Unlike traditional methods that prioritize execution after decisions are made, LPDS actively involves the customer in defining what they want, ensuring alignment from the outset. This isn’t just a philosophy; it’s a structured system designed to maximize value and minimize waste.

Зміст

What is LPDS?

LPDS is best understood as a temporary, project-based production system. Its core principle is questioning what needs to be done and who is responsible, right from the project’s inception. This contrasts sharply with conventional approaches where these questions are often deferred until later stages, leading to costly rework and misaligned expectations.

Key Characteristics of LPDS

The LPDS framework rests on four pillars:

- Value Generation: Projects are structured to deliver tangible value at every step.

- Early Stakeholder Involvement: Downstream stakeholders are engaged from the beginning, shaping the project through cross-functional teams.

- Pull Techniques: Information and material flow are managed using pull systems, ensuring resources are delivered when needed, not before.

- Buffer Optimization: Buffers are strategically used to absorb variability, ensuring smooth execution and minimizing disruptions.

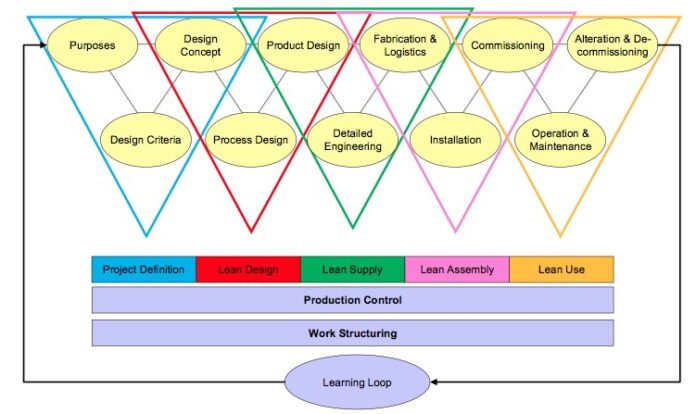

The Overlapping Phases of LPDS

LPDS operates through four interconnected phases: Project Definition, Lean Design, Lean Supply, and Lean Assembly, transitioning into Lean Use. Each phase overlaps with the next, creating a continuous flow of information and execution.

- Project Definition: Clarifies the project’s goals, means, and constraints through collaborative conversation.

- Lean Design: Develops the process and product design based on the conceptual framework, making decisions at the “last responsible moment” to maximize customer value.

- Lean Supply: Focuses on detailed engineering, fabrication, and delivery of components, minimizing inventory and lead times.

- Lean Assembly: Executes construction activities at the last responsible moment to avoid change orders and rework, culminating in commissioning and facility use.

- Lean Use: Considers long-term operation, maintenance, and decommissioning, delivering sustained value and a lower Total Cost of Ownership.

Integrating Work Structuring and Continuous Learning

Every phase of LPDS incorporates Work Structuring to break down complex tasks into manageable parts, and Production Control to govern execution rather than simply detect variances. Crucially, LPDS integrates a Learning Loop, enabling continuous adjustment and improvement at every step.

Methods within LPDS

Several methods are integral to the LPDS framework:

- The Last Planner® System (LPS): Serves as the production control mechanism.

- Target Value Design (TVD): Ensures projects meet customer satisfaction and constraints.

- Set-based design (SBD): Avoids unnecessary iteration by exploring multiple options simultaneously.

Implementing LPDS Successfully

Successful implementation of LPDS requires strong collaboration, early stakeholder involvement, aligned incentives, and seamless integration across all project participants.

In conclusion, the Lean Project Delivery System offers a collaborative, value-driven approach to construction that prioritizes customer satisfaction, minimizes waste, and promotes continuous improvement. It represents a fundamental shift from traditional methods, emphasizing proactive engagement and dynamic adaptation throughout the entire project lifecycle