Large construction projects differ dramatically from smaller builds like homes. The sheer scale introduces complexity that simple project management alone can’t handle. To maximize efficiency, multiple “lean” systems must be strategically linked together. These systems, like Glenn Ballard’s Last Planner® System (LPS), aren’t standalone solutions; they become more powerful when combined.

Зміст

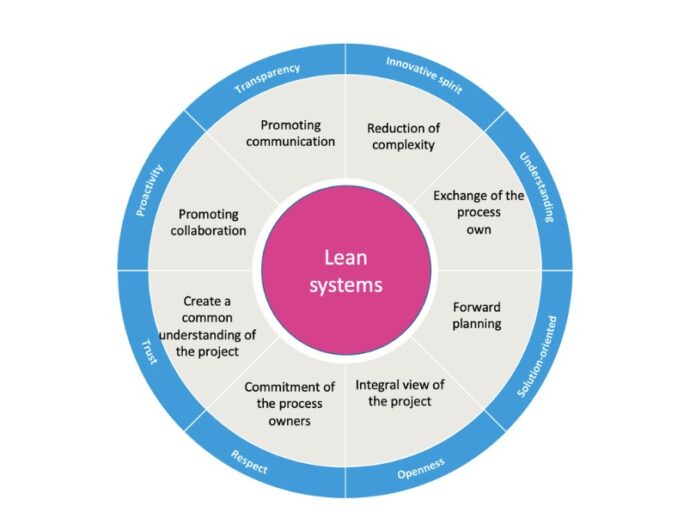

What Defines a Lean System?

A lean system operates within defined boundaries, tailored to the project’s complexity. Some processes can be streamlined; others require breakdown into smaller, manageable steps. Unlike rigid critical path methods (CPM), lean focuses on interfaces between teams and ensuring smooth flow of work.

The core goal is flow efficiency, driving improvements in:

- Reducing project complexity

- Strengthening communication between teams

- Proactive forward planning

- A holistic view of the project

- Ensuring commitment from all involved

- Establishing common understanding

- Improving collaboration

- Enhanced communication

Prerequisites for Lean Implementation

To achieve true flow efficiency, several key deliverables (or “artifacts”) are essential:

- Project milestones

- Comprehensive process analysis

- Weekly and daily look-ahead planning

- KPI-driven improvement management with action plans

- Risk assessment matrices

These aren’t just checklists; they’re active tools that track progress, identify bottlenecks, and drive adjustments.

Coupling Lean Systems: Series vs. Parallel

Linking multiple lean systems creates a “multi-lean” system. The coupling method depends on the project’s nature:

- Series connection: Best for sequential work, where one phase must finish before the next begins.

- Parallel connection: Suited for simultaneous tasks, like floors under construction while interior work progresses.

The optimal approach depends on factors such as project stage, design readiness, organizational structure, team experience, and project scope.

Information Flow: Managing Interfaces

Series-connected systems require clear interfaces managed by a lean manager. This person ensures information flows smoothly between phases.

Parallel systems need a central coordination point – often a “big room” where project leads can address issues arising from each subsystem. Transparency is key.

Setting Up an Overarching Multi-Lean System

The process mirrors the LPS approach: start with an Overall Process Analysis (OPA) and Milestone & Phase Plan (MPP) to define the project’s structure. Follow with detailed 6-Week Look Ahead planning (daily basis) to clarify interfaces. Track progress using risk matrices and KPIs, and proactively address issues in action plans.

A consistent approach – driven by experienced lean coaches – ensures all systems provide the same information, eliminating confusion.

Roles Within a Lean System

- Project Manager: Oversees the project’s economic and operational success.

- Technical Planners/Specialists: Implement technical details, often with support from site managers.

- Lean Specialists: Neutral facilitators who guide transformation without personal project interests.

- Process Owners: Actively participate in transparent communication across all levels.

Short, weekly meetings (Production Evaluation & Planning) drive accountability and ensure milestones stay on track.

The Value of Multi-Lean Systems

Multi-lean systems maintain a holistic view while allowing for necessary detail. Each system is tailored to the specific project and can be adapted as conditions change. The ultimate goal is on-time, on-budget completion.

In conclusion, leveraging multiple interconnected lean systems isn’t just a best practice; it’s a necessity for complex construction projects. By linking efficiency across phases, teams can avoid delays, minimize waste, and deliver successful outcomes.